CU2 ATEX

Wide-ranging rectangular fire damper up to 120’

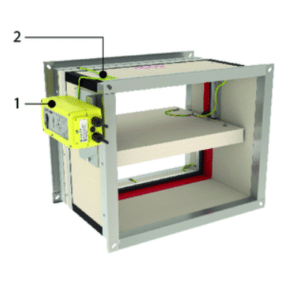

The CU2 ATEX is an explosion protected rectangular fire damper for use in zone 1,2 (gas) and zone 21,22 (combustible dust). The rectangular fire damper is EIS60 classified and suitable for built-in installation.

Available dimensions (Hn/Wn): 200×200 mm > 1500x1000mm

Components:

|

|

Features:

- Hygiene certificate (www.HYG.de) for CU2: H > 600 or W > 800

- Tested according to EN 1366-2 up to 500 Pa

- Suitable for built-in installation

- Minimal distance allowed

- Suitable for rigid wall, rigid floor and light wall (metal stud gypsum plasterboard wall, gypsum blocks)

- Sealing with fire resistant stone wool boards allowed, also for asymmetric opening

- Air tightness in accordance with EN 1751: class B (class C in option )

- Operating mechanism outside the wall

- Maintenance-free

- For indoor use

- Operating temperature: max. 50°C

- Intermediate dimensions on request

Mechanisms:

Download Technical datasheet KIT

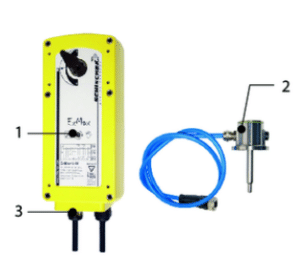

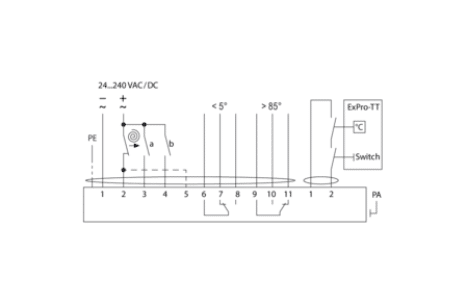

| Explosion proof (ATEX) motor for different risk areas: • Zone 1/21: average risk of explosion >100h/year explosive environment • Zone 2/22: low risk of explosion <10h/year of explosive environment |

VARIANTS

- RMEX

explosion proof actuator zone 2/22 - RMEXT

explosion proof actuator zone 2/22 with thermo-electric fuse (T) - EMEX

explosion proof actuator zone 1/2/21/22 - EMEXT

explosion proof actuator zone 1/2/21/22 with thermo-electric fuse (T)’

UNLOCKING

- manual unlocking

n.a. - automatic unlocking

as soon as the reaction temperature (72°C) of the thermo-electric tripping device is reached (Types EMEXT/RMEXT). - remote unlocking

by interrupting the power supply.

RESETTING

- manual resetting

use the delivered socket wrench, turn in slow motion and apply enough torque/force. - motorised resetting

supply the actuator (respect the prescribed voltage) for at least 60 sec. The resetting stops automatically.

Download the technical brochure of the CU2 series

Dear,

Thank you for expressing interest in our products. We are delighted to provide you with the technical brochure of the CU2 series. We appreciate your enthusiasm and look forward to assisting you further on your journey.

To download the brochure, please click the button below:

We hope that our product brochure provides you with comprehensive insights into the features and benefits of the CU2 series. If you have any questions or require additional information, please don’t hesitate to reach out to our friendly sales & support team.

Thank you again for choosing Rf-Technologies.

Best regards,

Tony Readdy

Technical Sales Expert UK

M. 07939 316006 | tony.readdy@rft.eu