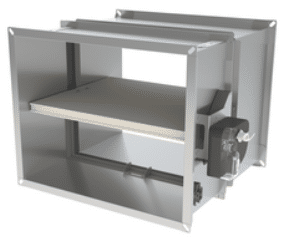

Rectangular fire damper CU-LT-L500

Optimised rectangular fire damper up to 120′

The CU-LT L500 rectangular fire damper has a fire resistance of 120 minutes. A tunnel casing extension at the wall side is also a part of the rectangular fire damper. This facilitates the connection to the duct when the supporting construction is thicker than 100 mm.

Available dimensions (Hn/Wn): 200×100 mm > 800x600mm

Benefits:

- Easy to install rectangular fire damper

- Optimal free air passage and minimal pressure loss

- Optimal acoustic performance

- Higher net building volume through compact size

- Air-tightness class C according to EN1751

- EIS60 classification

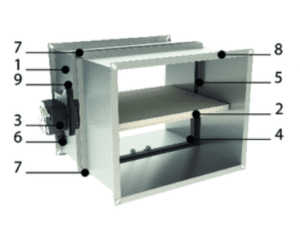

Components:

|

|

Features:

- Hygiene certificate (www.HYG.de)

- Tested according to EN 1366-2 up to 500 Pa

- Rectangular fire damper suitable for built-in installation

- Suitable for installation remote from the wall

- Minimal distance allowed for this type of rectangular fire damper

- Suitable for installation in rigid wall, rigid floor, flexible wall and flexible shaft wall (metal stud gypsum plasterboard wall)

- Sealing with fire resistant stone wool boards allowed, also for asymmetric opening

- Operating mechanism of the rectangular fire damper is outside the wall

- Maintenance-free

- For indoor use

- Intermediate dimensions on request

- Operating temperature: max. 50°C

Mechanisms:

Download Technical datasheet KIT

VARIANTS

- MFUS

Mechanism with fusible link

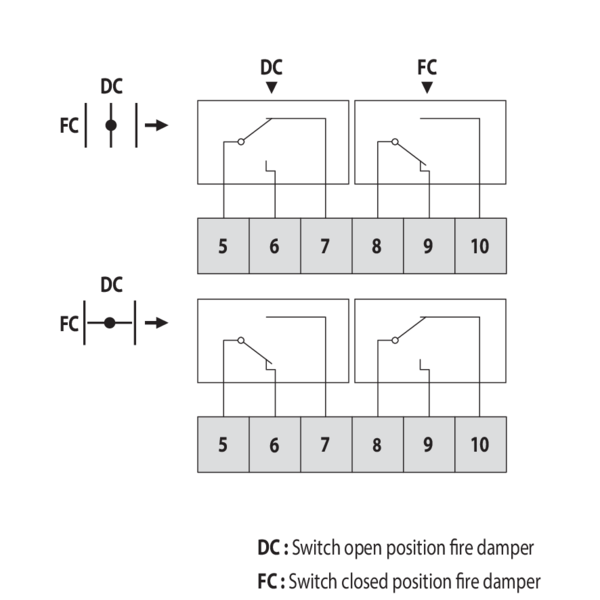

OPTIONS – SWITCH

- FDCU

Limit switch ‘open/closed’

UNLOCKING

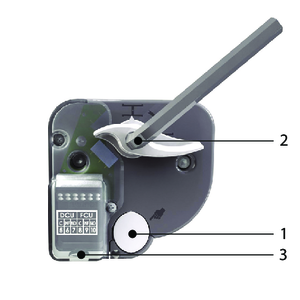

- manual unlocking

press the unlocking button (1). - automatic unlocking

the fusible link melts when the temperature reaches 72°C in the duct. - remote unlocking

n/a

RESETTING

- manual resetting

turn the resetting handle (2) 90° clockwise (or use a 10 mm hex key). - motorised resetting

n/a

Download Technical datasheet KIT

VARIANTS

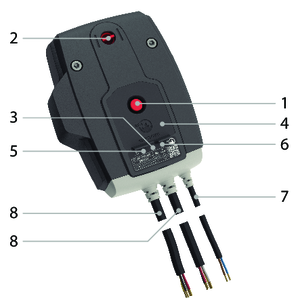

- ONE T 24 FDCU ST

Spring return actuator ONE 24V (with fusible link) + unipolar beginning- and end-of-range switch and plug (ST) - ONE T 24 FDCU

Spring return actuator ONE 24V (with fusible link) + unipolar beginning- and end-of-range switch - ONE T 230 FDCU ST

Spring return actuator ONE 230V (with fusible link) + unipolar beginning- and end-of-range switch + plug (ST) - ONE T 230 FDCU

Spring return actuator ONE 230V (with fusible link) + unipolar beginning- and end-of-range switch - ONE T 24 FDCB

Spring return actuator ONE 24V (with fusible link) + bipolar beginning- and end-of-range switch - ONE T 230 FDCB

Spring return actuator ONE 230V (with fusible link) + bipolar beginning- and end-of-range switch

UNLOCKING

- manual unlocking

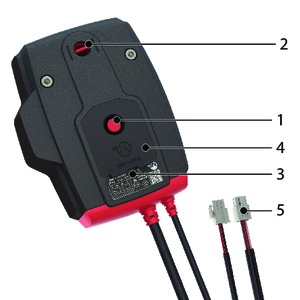

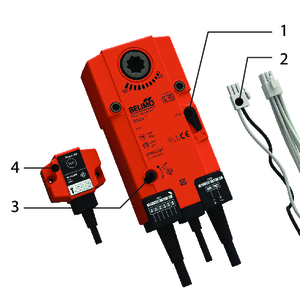

shortly press the unlocking button (1) once. - automatic unlocking

the fusible link reacts as soon as the temperature in the duct reaches 72°C. - remote unlocking

by interrupting the power supply.

RESETTING

- manual resetting

open the battery compartment (4) and press a 9V battery against the contact springs. Hold this position until the LED (3) emits a continuous light. Check whether the indicator (2) shows that the damper blade is in the open position. Remove the battery, the LED fades away. Close the battery compartment. - motorised resetting

switch off the power supply for at least 5 sec. Power the actuator (respect the prescribed voltage) for at least 75 sec. The resetting stops automatically when the end of range is reached (damper open).

Download Technical datasheet KIT

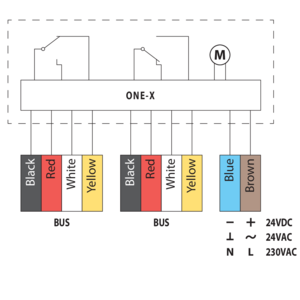

| The ONE-X is a spring return actuator with integrated communication module designed to simply operate Rf-t fire dampers of all sizes, automatically or remotely. The ONE-X is available in two versions: 24 V and 230 V.

|

VARIANTS

- ONE-X 24

Spring return actuator ONE-X 24V (with fusible link T) with integrated communication module - ONE-X 230

Spring return actuator ONE-X 230V (with fusible link T) with integrated communication module

UNLOCKING

- manual unlocking

shortly press the unlocking button (1) once. - automatic unlocking

the fusible link reacts as soon as the temperature in the duct reaches 72°C. - remote unlocking

via ZENiX controller

RESETTING

- manual resetting

Open the battery compartment (4) and press a 9V battery against the contact springs. Hold this position until the red LED (3) emits a continuous light. Control whether the indicator (2) indicates that the damper blade is open. Remove the battery. Close the battery compartment. - motorised resetting

via ZENiX controller. By applying voltage during first use.

Download Technical datasheet KIT

VARIANTS

- BFL24

Spring return actuator BFL 24V - BFL24-ST

Spring return actuator BFL 24V with plug (ST) - BFL230

Spring return actuator BFL 230V - BFLT24

Spring return actuator BFL 24 V with thermo-electric fuse (T) - BFLT24-ST

Spring return actuator BFL 24 V with thermo-electric fuse (T) and plug (ST) - BFLT230

Spring return actuator BFL 230 V with thermo-electric fuse (T) - BFLT230-ST

Spring return actuator BFL 230 V with thermo-electric fuse (T)

OPTIONS – SWITCH

- SN2 BFL/BFN

Auxiliary limit switch ‘open/closed’

UNLOCKING

- manual unlocking

place the locking button on “unlock”. (In case of BFLT: the damper can alternatively be unlocked by pushing the “test” button on the thermo-electric fuse) - automatic unlocking

the thermo-electric fuse reacts as soon as the temperature reaches 72°C (type BFLT). - remote unlocking

by interrupting the power supply.

RESETTING

- manual resetting

turn the enclosed handle anti-clockwise. To block the motor, place the locking button on “lock” - motorised resetting

switch off the power supply for at least 10 seconds. Supply the actuator (respect the prescribed voltage) for at least 75 seconds. The resetting stops automatically when the end of range is reached (damper open) – it takes about 60 seconds to reset the damper – or when the power supply is interrupted.

Download the technical brochure of the CU-LT series

Dear,

Thank you for expressing interest in our products. We are delighted to provide you with the technical brochure of the CU-LT series. We appreciate your enthusiasm and look forward to assisting you further on your journey.

To download the brochure, please click the button below:

We hope that our product brochure provides you with comprehensive insights into the features and benefits of the CU-LT series. If you have any questions or require additional information, please don’t hesitate to reach out to our friendly sales & support team.

Thank you again for choosing Rf-Technologies.

Best regards,

Tony Readdy

Technical Sales Expert UK

M. 07939 316006 | tony.readdy@rft.eu

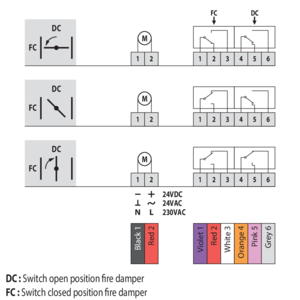

_electrical%20wiring.png)